Sales Hotline:

+86-13793088586

Sales Hotline:

+86-13793088586Problems with conventional structures

Automobiles used to use bearings, which consisted of two sets of tapered roller or ball bearings spliced together. In automobile production, the steps of mounting the bearings, applying lubricant, sealing treatment and adjusting the clearance were quite complicated. This design is not only difficult to assemble, but also very costly and unreliable. When it comes to the maintenance stage, the bearings also have to be cleaned, lubricated and adjusted, a process that is both time-consuming and labour-intensive.

Unit advantages come to the fore

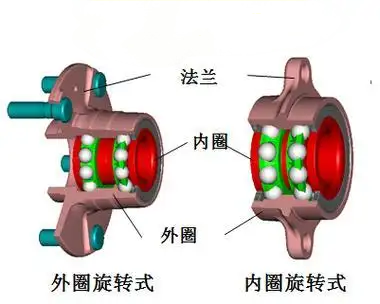

The wheel bearing assembly is a combination of a standard angular contact ball bearing and a tapered roller bearing. This assembly combines two bearings in one and offers many advantages. For example, it is easy to mount and requires no clearance adjustment; it is lightweight and compact; it has excellent load carrying capacity and can be pre-greased. It is now widely used in cars and is also showing a gradual increase in use in the heavy-duty vehicle sector.

Installation tool points

Wheel bearings are rigorous and must be installed according to the correct procedures and with the right tools. Extra care must be taken during storage and assembly to prevent damage to the parts. Some bearings require greater force to mount, at which time specialised equipment must be used. In addition, when assembling, it is also necessary to refer to the relevant guidance of automobile manufacturing to ensure that the operation is in line with the standard, otherwise it may affect the normal use of bearings.

Avoid improper handling

Wheel bearing parts should not be disassembled casually, and sealing parts should not be changed casually. Once the seals are damaged, water and dirt can enter, preventing the bearings from functioning properly for long periods of time. It is important to ensure that they are in good condition and operate according to the established design specifications, so as to ensure that the performance of the car is not compromised.

Lubrication Techniques

Bearings are commonly sealed and do not require additional grease for use. However, for those double row Tapered Roller Bearings that are not sealed, lubrication must be applied during assembly. Precise control of the amount of lubricant is a challenge, and it is generally necessary to ensure that the lubricant fills approximately half of the bearing gap. If too much lubricant is applied, leakage may occur when the bearing is rotating.

Routine Inspection and Maintenance

In order to ensure safe driving, we must carry out regular inspections of the wheel bearings. During inspection, look for abnormal friction noise when the wheels are turning, and also observe whether the suspension combination wheels can decelerate smoothly during cornering. When the rear wheel drive section of the vehicle reaches 38,000 kilometres, the front wheel hub bearings should be lubricated and serviced. When replacing the brake system, remember to check and replace the oil seals as well.

Clean installation environment

The bearings must be installed in a clean environment, otherwise the life of the bearings is likely to be shortened if small particles are mixed in. Never use a hammer for hammering to prevent dust adhesion. It is important to inspect the axle and housing before mounting, as any minor wear may cause them to mismatch and lead to premature failure.

Do you usually take care to check the maintenance status of your car's axles? If you find this article inspiring, please follow us and share it with your friends to check it out!

| ||