Sales Hotline:

+86-13793088586

Sales Hotline:

+86-13793088586

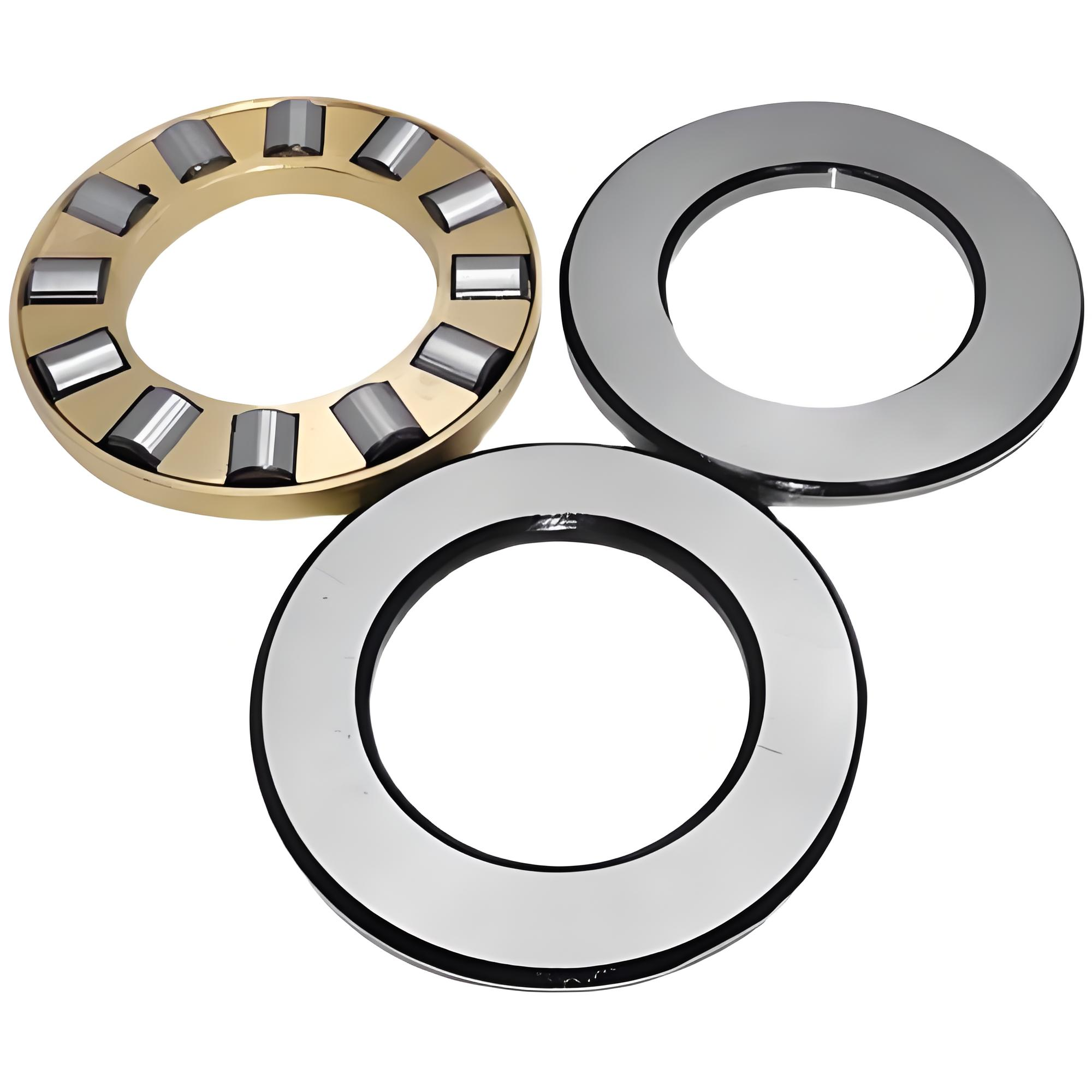

Thrust Roller Bearings are used for shafts that primarily bear axial loads and combined radial loads, but the radial load must not exceed 55% of the axial load. Compared to other thrust roller bearings, this type of bearing has a lower friction coefficient, higher speed, and self-aligning performance.

Notes

1. Selection and control of tolerance for thrust roller bearing housing: After the thrust roller bearing is pressed into the thrust roller bearing housing, it should rotate smoothly without any resistance. If there is noticeable stiffness in rotation, this indicates that the shaft dimensions are too large, and the tolerances should be adjusted downward. If there is a noticeable ‘squeaking’ sensation when manually rotating the thrust roller bearing after it is pressed into the shaft, this may be due to excessive shaft tolerances or poor shaft roundness. Therefore, while controlling the tolerances of the shaft and thrust roller bearing housing, it is also essential to control roundness. Many domestic manufacturers only control tolerances and do not control roundness.

2. Assembly method for thrust roller bearings: Since thrust roller bearings are high-precision products, improper assembly can easily damage the bearing raceway, leading to bearing failure. When assembling thrust roller bearings, specialised moulds should be used, and they should not be struck arbitrarily. When pressing the shaft, only the inner ring should bear the force, and when pressing the outer ring, only the outer ring should bear the force. During assembly, pneumatic or hydraulic pressure should be used. When pressing, the upper and lower moulds must be in a horizontal state. If there is any tilt, it may cause damage to the raceway of the thrust roller bearing due to uneven force distribution, resulting in abnormal noise.

3. Prevention of foreign object contamination: During dynamic balancing of thrust roller bearings on the rotor, metal shavings generated during balancing can easily enter the bearing interior. Therefore, it is best to perform dynamic balancing before installing the thrust roller bearing. Some manufacturers apply oil or grease to the thrust roller bearing housing during assembly for lubrication purposes. However, operators often struggle to control the amount applied. If excessive oil or grease accumulates in the housing, it may enter the bearing interior along the shaft during rotation. It is best not to apply oil or grease to the thrust roller bearing housing. If application is unavoidable, ensure that no residue remains inside the housing.

4. Prevention of paint rust: Paint rust typically occurs in sealed motors. During assembly, the motor operates smoothly, but after being stored in a warehouse for some time, abnormal noise becomes significant. Upon disassembly, severe rusting of the thrust roller bearing is observed. Previously, many manufacturers attributed this issue to the thrust roller bearings. However, after our continuous efforts to raise awareness, motor manufacturers have recognised that the primary cause is the insulation paint. This issue arises because the acidic substances emitted by the insulation paint form corrosive substances under certain temperature and humidity conditions, which corrode the raceways of the thrust roller bearings and cause their failure. This issue can only be addressed by selecting high-quality insulation paint and allowing it to ventilate for a period of time after drying before assembly.