Sales Hotline:

+86-13793088586

Sales Hotline:

+86-13793088586bearings, seemingly tiny mechanical components, have woven a chorus through humanity's entire technological evolution, from primitive transportation to interstellar exploration. They are not only silent witnesses of industrial progress but also crucial enablers of civilization's evolution. From the earliest wooden rollers to modern ceramic and magnetic levitation systems for use in extreme environments, every innovation in bearings has been closely aligned with the needs of the times.

Ancient Mechanical Wisdom: The Exploration of "Low Friction" at the Beginning of Civilization

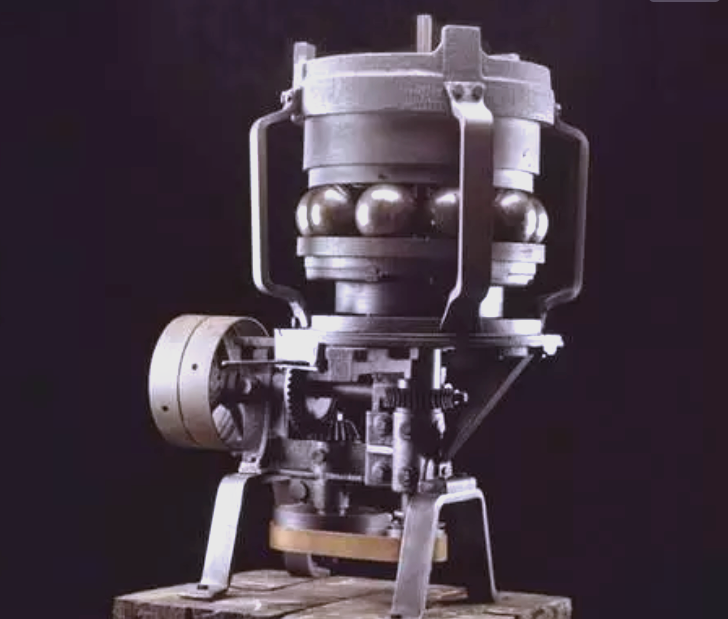

At the end of the 19th century, bearings officially entered the era of precision manufacturing. In 1883, the German company FAG developed the world's first steel ball grinding machine, enabling high-precision mass production of steel balls and laying the foundation for the large-scale application of modern rolling bearings. The rapid development of railway transportation in the 20th century brought new challenges: frequent overheating of train axleboxes due to misalignment.

In 1914, SKF introduced the double-row self-aligning ball bearing, effectively resolving this problem and significantly improving operational safety and maintenance cycles, becoming a key technological support for the industrialization of railways.

Modern Breakthroughs in Cutting-Edge Scenarios: Challenging the Limits of Physics

Entering the 21st century, bearing technology has penetrated even the most challenging areas of human endeavor. In the precision robotic arms of space stations, the bearings used in harmonic reducers must operate continuously in a vacuum environment for millions of cycles without lubrication, testing the material's outgassing rate and resistance to cold welding. Inside nuclear reactor main pumps, silicon nitride ceramic bearings can operate stably at temperatures of 350°C and in strong radiation environments, replacing metal components for a longer service life. Tesla's 4680 battery production line utilizes a magnetic levitation bearing drive system, achieving completely contactless, zero-friction transmission and ensuring efficient and stable operation in its ultra-clean workshop.

Current Facts and Technological Leaps: A Millennium of Materials Transformation

History is filled with examples of bearing failures changing the course of battle. According to historical analysis, Napoleon's army's defeat in Russia in 1812 was partly due to widespread seizure of bronze bearings in chariots due to freezing and rusting of lubricants in the severe cold, severely impacting logistics.

From a material perspective, the evolution of bearing hardness can be described as a miniature industrial history: early wood hardness was about HB50, gradually developed to bearing steel HRC60 or above, and then to modern ceramic materials HV2000+, and even artificial diamond coatings (HV9000) used in special occasions, achieving an exponential leap in load-bearing capacity and durability.

| ||